The roof is an extremely important part of any construction, and proper roof truss design and installation are vital for keeping the roof in shape and in place. However, choosing the best roof truss design isn’t always easy.

So, how do you create strong, efficient and code-compliant roof structures? By discovering key design principles, material choices, load considerations and more, you can achieve successful installation and structural integrity in every project.

Understanding Roof Trusses

A roof truss is a crucial structural component designed to safely support a roof and maintain its structural integrity.

They help bear and distribute the weight of a roof (as well as anything on top, like snow or rain), spreading it to the outside walls of the building. Roof trusses are typically made of either timber, steel or a combination of the two. They can be designed and built from scratch or sold as prefabricated products ready for installation.

Compared to squares or rectangles, triangular shapes are strong and withstand weight and pressure well, which is why roof trusses are comprised of interconnected triangular structures.

Various designs are used in construction projects. However, roof trusses always include the following parts: a bottom chord (the horizontal beam at the bottom), a top chord (the beams at the side), a web (the interior beams that connect the chords) and a pitching point (where the top chords meet).

Types of Roof Trusses

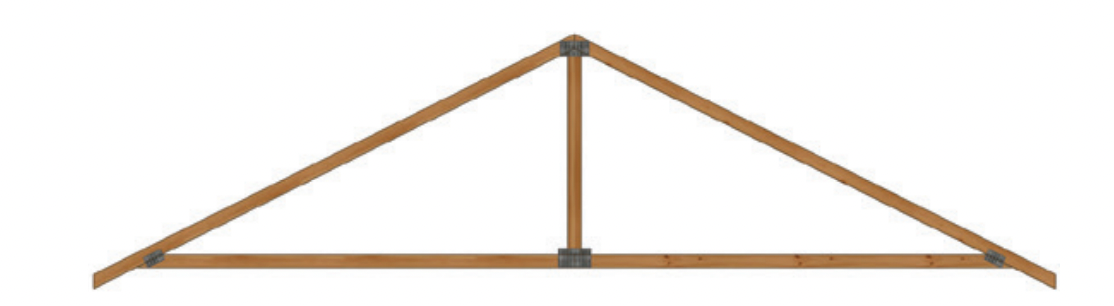

King Post Roof Truss

The king post truss consists of a central vertical post (known as the king post), a horizontal bottom chord and two top chords. It is known for being reliable, quick and simple to build. It’s effective for low-to-moderate load-bearing requirements.

This option allows for wider span lengths due to the support from the center post. It’s also cost-effective as it makes efficient use of just a few materials.

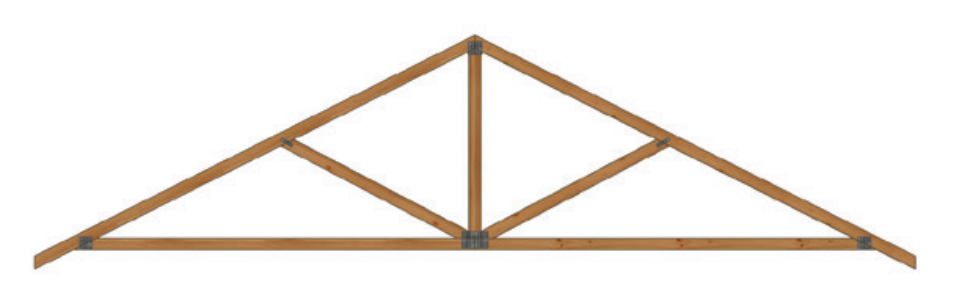

Queen Post Roof Truss

Similar to the king post truss, the queen post truss is particularly effective for longer spans. This design features two vertical posts and a horizontal strut for extra support.

This option has similar load-bearing capabilities as the king post truss, although it’s slightly more costly due to the additional posts and struts.

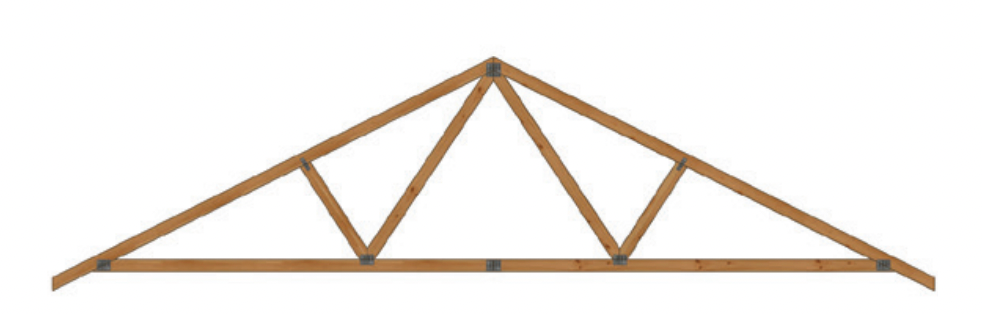

Fink Roof Truss

The fink roof truss is one of the most popular options for residential projects. It includes a more complex web of diagonal beams and offers a high level of weight distribution, making it ideal for projects that require greater load-bearing capabilities.

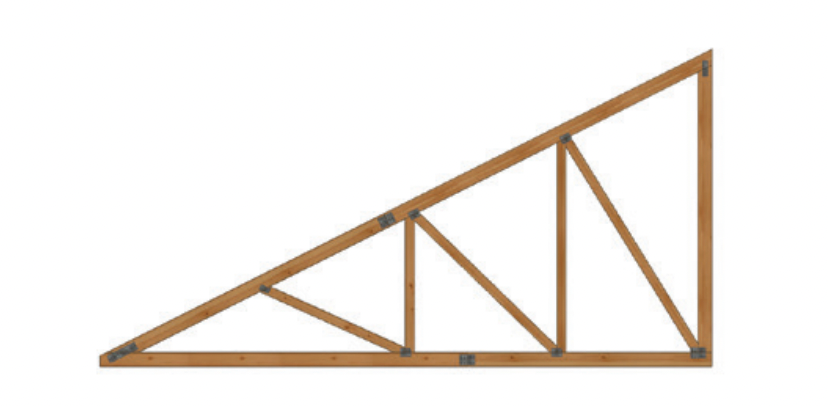

Scissor Roof Truss

The scissor roof truss design includes diagonal bottom chords, mirroring the shape of a pair of scissors. An interior web also offers additional load distribution.

Scissor trusses are ideal for buildings with shorter spans and those with open-plan designs, as the scissor design adds vertical space inside the building. This option costs more than other designs, but can be advantageous for commercial projects where a unique aesthetic is desired.

Key Design Considerations

Load Calculations

Calculating loads is crucial to avoid structural damage. Load path analysis is the process of determining how the trusses distribute weight around the entire building structure, helping designers decide where to place trusses and connections.

As well as bearing weight, roof trusses must also withstand seismic forces and wind, which can exert pressure from all directions. If load calculations are insufficient, damage and even injury can happen. That’s why working with a professional contractor is recommended for this step.

Span and Pitch

Span refers to the distance from one end of the bottom chord to another and must match the span of the building itself. Pitch refers to the angle of the top chords and is displayed as a ratio of “rise” (verticality) to “run” (horizontality).

For example, 3/10 would mean three inches of rise for each 10 inches of run. Not only do span and pitch impact the aesthetics of a roof, but they also play a role in its load-bearing capabilities.

Material Selection

Choosing optimal materials is a key aspect of successful roof truss design, as they will impact the integrity and durability of the entire structure. Your choice of materials will also affect the cost of your project.

The two most popular choices are steel and timber. While steel offers the ultimate strength, heat resistance and longevity, high-quality wood is more than tough enough for most projects.

Steel is usually chosen for commercial buildings where extreme load-bearing and fire resistance capabilities are paramount, but it usually costs more than timber.

Another important material to consider is the roof covering, which can range from lightweight metal to very heavy tiles. This will inform the durability and required load-bearing capabilities of your trusses.

Common Mistakes to Avoid

Unfortunately, there are several mistakes that are commonly made when it comes to roof truss design and installation. These errors can lead to structural issues, added costs and even safety risks.

To follow best practices and ensure success, here are a few key things to keep in mind:

Neglecting Safety Protocols

Always wear the correct personal protective equipment (PPE) and follow all relevant OSHA guidelines. Roofing is inherently dangerous work and ignoring safety procedures can result in serious injury. Proper training, fall protection and secure scaffolding should be the highest priority on every job.

Starting Without Finalized Plans

Before installation begins, ensure your truss layout, foundation measurements and structural calculations are finalized and approved. Trusses are manufactured to precise specifications, and any deviation can result in misalignments or costly rework.

Using Incorrect Connector Plates or Bracing

Using the wrong size connector plates or failing to apply proper bracing is a common oversight. Incorrect connector plates or bracing can cause bowing, shifting or even collapse of the trusses.

Poor Handling of Trusses

Dropping or mishandling trusses can damage joints and plates, compromising their structural integrity. Always store trusses on a flat surface, off the ground and protected from the elements to avoid warping or moisture absorption.

Working with Engineers and Architects

To design and install roof trusses, you will need to collaborate with engineers and architects. Engineers will help you calculate loads, stress distribution and material requirements. Architects work to integrate the roof truss design into the building’s overall design, aesthetic and layout.

When working with professionals, clear communication between all parties is vital and will help you avoid delays and conflicts. As a team, discuss and agree upon factors like roof pitch, span lengths, load paths and ceiling profiles.

Alternatively, you can opt for prefabricated, engineered trusses. This option offers convenience, efficiency and cost savings. However, personalized options may be limited compared to designing roof trusses from scratch.

Berry Home Centers Can Help

At Berry Home Centers, we provide top-quality roof truss products to customers all across the Southwest Virginia/Northeast Tennessee region.

We also offer many other building materials and products, including lumber, tools and paint, making us a one-stop shop for all your job needs.

Ready to get started on your roofing project? Check out our offerings today or get in touch with our team to request a quote.